Fiber Laser Cutting Machine

Home > Products > Fiber Laser Cutting Machine

Sheet Metal Laser Cutting Machine Manufacturer in India

Pusaan Automation Pvt. Ltd. is India’s topmost fiber laser cutting machine manufacturer. We provide you with many sheet metal laser cutting machines; we are the best fiber laser cutting machine manufacturer and supplier in India. We also have a premium range of Sheet Metal Laser Cutting Machine, CNC Laser Cutting Machine, CNC Metal Laser Cutting Machine and Laser cutting machine for metal. As you are aware, the industries have benefited from amazing advantages from the recent, one-by-one advances in technology. Thanks to these technologies, the work is finished fast and easily, and the outcomes are also excellent. Right now, we are talking about the sheet metal industries, which are using these technologies to increase production and make a lot of money. As a result, we have made you an offer for an affordable, high-quality sheet metal laser cutting machine. Our fiber laser cutting machine is more cost-effective, better built, and made of higher-quality materials than other goods on the market. To make sure that our products survive as long as possible, we also employ the latest and most advanced technologies. To avoid problems in the future, all of our products are manufactured under the guidance of our team of specialists. Investing in an industrial fiber laser cutting machine is a major step for any business. It’s a decision that can dramatically increase your production capacity, improve part quality, and open up entirely new market opportunities. But with a significant investment on the line, it’s critical to get it right.

Pusaan Automation Pvt. Ltd. is a well-known company that constantly achieves the trust of its clients and makes stronger connections with them. Our sheet metal laser cutting machine is affordable prices and of excellent quality when it comes to its price in India. We provide the best models of laser cutting machines for cutting sheet metal and we are the best manufacturer and supplier of fiber laser cutting machine in India. A metal with an excellent cutting surface is produced by our powerful laser cutting machine for metal. This technology helps to improve your product quality.

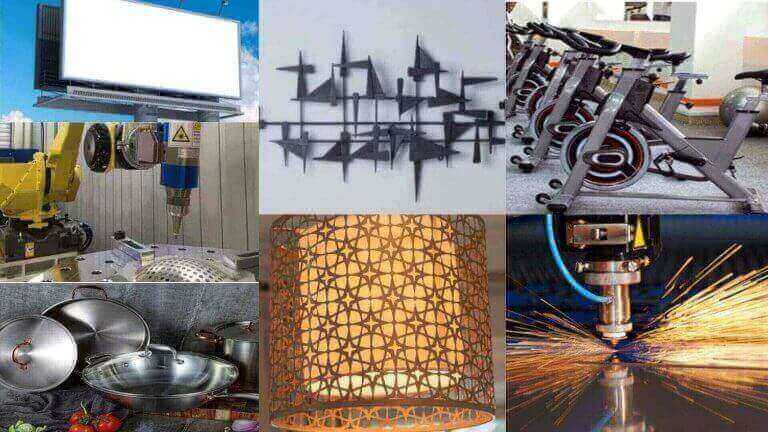

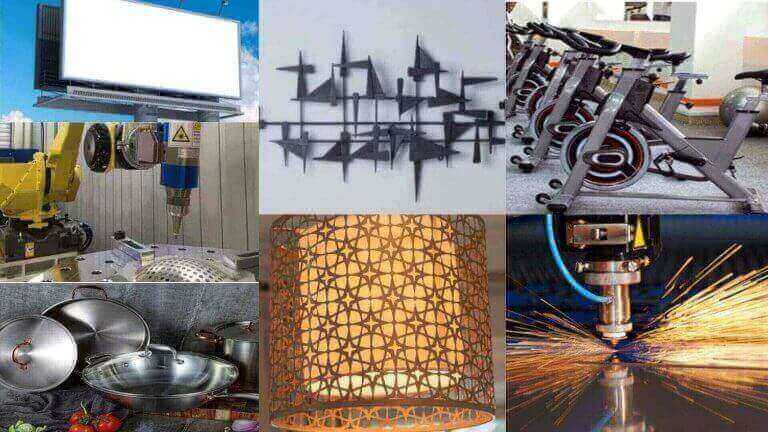

Today, fiber laser machines are used in many other industries, including advertising, lighting, automobiles, sports equipment, and decorative sectors. The technology of the CNC metal laser cutting machine is also utilized by several metal companies. Additionally, you may view the best CNC plasma cutting machine models.

Open Type Fiber Laser Cutting Machine

Open Type Fiber Laser Cutting Machine

Technical Chart

| Modal | PSL 3015 | PSL 4015 | PSL 5015 | PSL 4020 | PSL 6020 |

|---|---|---|---|---|---|

| Track Width (mm) | 1500 | 1500 | 1500 | 2000 | 2000 |

| Track Length (mm) | 3000 | 4000 | 6000 | 4000 | 6000 |

Technical Parameter

| Item | Technical Parameter |

|---|---|

| Laser Type | Fiber Laser Source IPG |

| Laser Wavelength | 1070-2080nm |

| Electro-optical conversion efficiency | 25-30% |

| XYZ axis working length | 3000mm/1500mm/120mm |

| Cutting thickness | MS0.5-12mm (Depend on materials) |

| Incision seam width | 0.1-0.2mm |

| Repeated position in accuracy | 0.05mm/1000mm |

| Traverse Speed | 100M/min |

| Maximum acceleration | 1.0G |

| Table maximum load | 800kg |

| Total machine weight | 4000kg Approx. |

| Power demand | 380V 50Hz/60Hz |

| Dimension (L x W x H) | 4600mm*2750mm*1500mm |

The metal body of this cutter was heat treated to 600 °C and allowed to cool in the chamber for a whole day. A plano-milling machine and welded carbonic acid gas are utilized where this is allowed. Thus, a twenty-year service life and high power are assured. A class-leading and highly efficient maximum acceleration rate of 1.0G, repeated position precision of 0.05mm/1000mm, and maximum running speed of 100 M/min are all present. An innovative design, simple integration, and the least amount of space needed for a machine of its quality make this a first for everywhere. Every single element, such as the border made of stainless steel, the LED indication design, and the control arm, radiates superb and ultimate elegance.

Using the most recent technologies and the highest levels of luxury, we manufacture industrial goods. Heat treatment at 600 °C and oven cooling for 24 hours To guarantee 20 years of operation without deformation, we use premium components. Autocollimator: to verify the accuracy of each machine set and examine the guide rails’ straightness. Because of its expert cutting parameter database, less operator labour is required since distinct cutting parameters can be automatically applied for different sheet metal materials at varying thicknesses. makes use of servomotors that were originally imported and has outstanding features integrated. Its great MS cutting thickness ranges from 0.5 to 12 mm, depending on the material. We provide an excellent open type fiber laser cutting machine with cutting-edge functions.

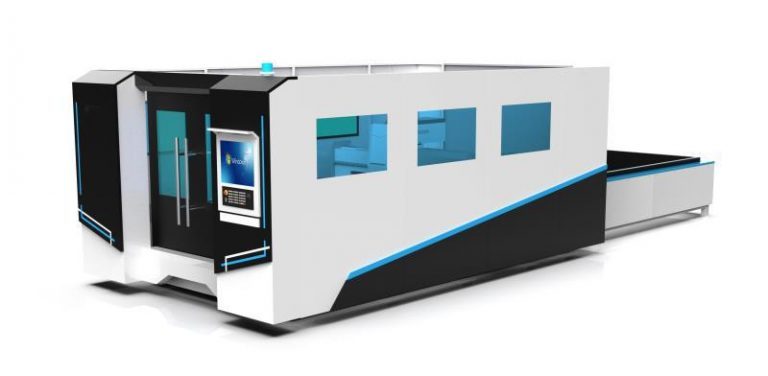

Exchange Table Type Fiber Laser Cutting Machine

Exchange Table Type Fiber Laser Cutting Machine

Technical Chart

| Modal | PSL 3015 | PSL 4015 | PSL 6015 | PSL 4020 | PSL 6020 |

|---|---|---|---|---|---|

| Track Width (mm) | 1500 | 1500 | 1500 | 2000 | 2000 |

| Track Length (mm) | 3000 | 4000 | 6000 | 4000 | 6000 |

Technical Parameter

| ITEM | TECHNICAL PARAMETER |

|---|---|

| Laser Type | Fiber Laser Source IPG |

| Laser wavelength | 1070-1080mm |

| Electro-optical conversion efficiency | 25-30% |

| XYZ axis working length | 3000mm/1500mm/120mm |

| Cutting Thickness | MS 0.5-12mm (Depend on materials) |

| Incision seam width | 0.1-0.2mm |

| Repeated position in accuracy | 0.03mm/1000mm |

| Positioning accuracy | 0.05mm |

| Traverse Speed | 140M/min |

| Maximum acceleration | 1.05G |

| Table maximum load | 800kg |

| Total machine weight | 5000kg |

| Power demand | 380V 50Hz/60Hz |

| Dimension (L x W x H) | 8500mm*2900mm*1900mm |

Exchange Table Type Fiber Laser Cutting Machine: Buy Now! We provide you with an amazing deal and savings. The control panel features a chrome steel border, the suspension lamp design is perfect, and we are making industrial goods to satisfy the market for high-end products. The machine’s technological expertise supplies the best electrical and driving systems, as our example below shows. We only make use of the greatest and the best-quality parts.

Sheet and Tube Fiber Laser Cutting Machine

Sheet and Tube Fiber Laser Cutting Machine

Technical Chart

| MODAL | PSL 3015 | PSL 4015 | PSL 6015 | PSL 4020 | PSL 6020 |

|---|---|---|---|---|---|

| Track Width (mm) | 1500 | 1500 | 1500 | 2000 | 2000 |

| Track Length (mm) | 3000 | 4000 | 6000 | 4000 | 6000 |

Technical Parameter

| ITEM | TECHNICAL PARAMETER |

|---|---|

| Laser Type | Fiber Laser Source IPG |

| Laser wavelength | 1070-1080nm |

| Electro-optical conversion efficiency | 25-30% |

| XYZ axis working length | 3000mm/1500mm/120mm |

| Cutting thickness | MS 0.8-12mm (Depend on materials) |

| Incision seam width | 0.1-0.2mm |

| Repeated position in accuracy | 0.03mm/1000mm |

| Positioning accuracy | 0.05mm |

| Traverse Speed | 800M/min |

| Maximum acceleration | 0.5G |

| Table maximum load | 800kg |

| Total machine weight | 5000kg |

| Power demand | 380V 50Hz/60Hz |

| Dimension ( Length x Width x Heigth ) | 4600mm*3600mm*1500mm |

Sheet and Tube Fiber Laser Cutting Machine: Buy Now! We can cut tubes and metal sheets in this machine. Raycuser source or IPG Available capacities range from 1 to 20 kW. The high power specialist cutting head can support strong and fast cutting. The power source generates the laser beam, which is then directly delivered to the cutting head and workpiece using the fiber cable. The machine’s strong and durable mechanical structure produced stable cutting performance. In addition to making sure there are no microcracks in the structure, we are doing heat treatment to relieve stress on the body. The machine’s controller is easy to use and has all the most recent updates. Quick pallet exchanger and complete body enclosure. We upgraded the machine with premium parts to provide you with an amazing experience and suitably increase your production.

Advantages of Fiber laser cutting Machine

Using a fiber laser cutting machine has various advantages. Many application industries, as you may know, employ this technology to boost productivity and grow their company rapidly. There are five main advantages of using a fiber laser cutting machine.

Boost in Cutting Speed—Fiber laser cutting machine have good cutting speeds; they can complete tasks quickly and at the best quality possible. A fiber-based laser can cut a straight line that is 1 mm thick faster than a traditional laser.

Superior Performance—You will discover that the performance of fiber lasers is better than that of many of their competitors. High-quality laser beams with increased power density and extremely high levels of accuracy can be achieved with fiber lasers by tightly focusing the beam.

Cutting Reflective Material—When using a standard laser, one of the most important considerations is the reflective material. It’s possible that the material will be damaged by a laser reflector striking it. This is the reason why cutting copper, brass, and aluminium with traditional lasers is rare. Fiber optic lasers, on the other hand, solve the problem of reflecting materials, making it possible to cut through these materials.

No Moving Parts—Moving parts are more expensive to operate and require more maintenance when they are absent. As light pulses are conveyed via fiber optic cabling, a moving mirror is not necessary to generate the necessary laser. Since just the cutting material comes into touch with the laser during cutting, no material is lost and offers the finest final cut.

Higher Electrical Efficiency—Power is saved each time the fiber optic design is used, and since less energy is used, the hardware’s lifespan is also extended. Any obstacle can be overcome using a laser cutter. Extremely small areas of material can be treated with powerful lasers almost entirely free of distortion or warping.

Less Expensive—The affordable cost of laser cutting is perhaps its most significant advantage. Using this strategy will save you money in the short term, but over the duration of the laser’s lifetime, it will save you a lot. One of its advantages over other laser technologies is that it does not require expensive optical reflectors. Moreover, instead of being exposed, the focusing lens is contained inside the cutting head. Therefore, in contrast to laser applications where damage and frequent replacement are necessary over the fiber optics’ lifespan, concentrating lenses only require damage under proper repair.

Laser Cutting Work & Process

An accurate and seamless transition is produced by moving a focused and precise laser beam across the material you are cutting. The beam first creates a hole at the edge of the material before continuing from that point. Melting is preferred to cutting since the laser basically melts the substance it comes into contact with. This implies that it can effortlessly cut light materials like stones like diamonds, metals, and textiles.

Both pulsed beam and continuous wave beam are options; the former is delivered in brief bursts while the latter operates continually. You may adjust the laser beam’s power, length, and heat output to suit the material you’re working with. You can also use a mirror or special lens to direct the laser beam in the direction you want it to go.

Some Design of Laser Cutting

Application Fields Using Fiber Laser Cutting Machine

Many manufacturing industries use this fiber laser cutting technology. And some application fields such as

- Automobile Industries

- Lightning Industries

- Fitness equipment

- Sheet metal industries

- Decoration industries

- Advertisement industries

- Kitchenware Industries

- Home Appliances

- Sports industries like fitness, cricket, badminton academies, golf, and many more industries.