Flame / CNC Plasma Cutting Machine

Home > Products > Flame / CNC Plasma Cutting Machine

CNC Plasma Cutting Machine Manufacturer in India

Pusaan Automation PVT LTD offers different types of CNC Flame/CNC Plasma Cutting Machine. We are the best supplier and manufacturer of CNC plasma cutting machines in India. We produce high-end machines using cutting-edge technology. Due to the high quality components we use in our machine, the pricing of our CNC plasma cutting machine is fair. You can look up the cost and output quality of an Indian CNC plasma cutting machine. Our plasma cutting machine quality and price in India are superior to those of our competitors. We frequently offer our clients a variety of options. Different varieties of CNC flame and plasma cutting machines, such as the bench-type plasma cutting machine, portable CNC plasma cutting machine, and Gantry Type CNC plasma cutting machine, are produced by Pusaan Automation PVT LTD. You can contact us for a great deal.

Gantry Type Flame / CNC Plasma Cutting Machine

This machine is used for facilitating the process of plasma cutting, which uses an accelerated jet of hot plasma to cut through electrically conducting materials. Furthermore, it is a well-liked option for applications in both large-scale enterprises and tiny hobbyist shops due to its fast speed and accurate cut.

Additionally, it is put through a variety of quality tests with expert supervision. Additionally, a variety of metals are cut using a CNC plasma cutting machine of the gantry type. Computers run plasma CNC machines, which use programmed instructions to make materials that adhere to exact requirements. The cutting torch is the standard tool used in plasma cutting machines to cut metal plates, sheets, bolts, pipes, etc. CNC plasma cutter machines have a system that can move the path of the plasma torch by computer. Pusaan Automation PVT LTD is the best gantry type CNC plasma cutting machine manufacturer in India. In the industrial world, our plasma cutting machine is highly regarded. Compared to a fiber laser cutting machine, a plasma cutter can easily cut materials that are the same thickness or thicker. When compared to other dealers and manufacturers, the price of the Gantry type CNC plasma cutting machine is reasonable. For more information about the Bench type machine and Portable CNC plasma cutting machine, see below

Gantry Type Flame / CNC Plasma Cutting Machine

Technical Chart

| MODAL | SC 3508 | SC 2506 | SC 3506 | SC 4008 |

|---|---|---|---|---|

| Track Width (mm) | 3500 | 2500 | 3500 | 4000 |

| Track Length (mm) | 8000 | 6000 | 6000 | 8000 |

| Cutting Head | One Flame and One Plasma | |||

Technical Parameter

| Description | Specifications |

|---|---|

| Maximum Cutting width (mm) | 3000-6000 |

| Maximum Cutting Length (mm) | 8000-20000 |

| Drive System | Double |

| Servo Motors | A.C Servo motors |

| Make of Servo Motors | Panasonic |

| Axis | Rack & Pinion on both side for longitudinal & cross Axis |

| CNC Controllers | Hypertherm |

| Height Sensor | Arc voltage with HIS & Anti Collision |

| Plasma Ctting Speed | According to the plasma power source |

Bench Type Plasma Cutting Machine

We have the experience to provide customers with a range of Bench Type Plasma Cutting Machine. In plasma cutting machines, a torch that cuts is a common tool used to cut metal sheets, metal plates, bolts, pipes, and other materials.

These machines are extensively used across multiple industries to give improved welded finish requirements. The suggested machines were designed in compliance with industry standards and requirements. In order to meet the individual needs of our clients, we also provide these machines in a range of configurations. All of our machines are inspected against set standards before being shipped in the end. Pusaan Automation is an India-based company that makes and offers services for plasma cutting machines. We constantly base our strategy on what our clients need. Additionally, the Bench Type CNC plasma cutting machine price is reasonable when compared to other dealers, and you can quickly contact the manufacturer to make a buy right now.

Salient features of these machines are listed below:

- Efficient operation

- Long-lasting performance

- Tested using various parameters

Bench Type Plasma Cutting Machine

Technical Chart

| MODAL | SC 2506 | SC 3506 | SC 3508 | SC 4008 |

|---|---|---|---|---|

| Track Width (mm) | 2500 | 3500 | 3500 | 4000 |

| Track Length (mm) | 6000 | 6000 | 8000 | 8000 |

| Cutting Head | One Flame and One Plasma | |||

Technical Parameter

| MODEL | BEN-1530 |

|---|---|

| Cutting Mathod | Plasma & Gas |

| Width | 1500 mm |

| Length | 3000 mm |

| Cutting totch lifting | 100 mm |

| Cutting speed | 0-10,000 mm/min |

| Minimum Moving speed | 12000mm min |

| Cutting thickness | According to the plasma power source |

| Gas cutting | Oxygen + Ethyne / Oxygen + Propane |

| power | Related power 2.0 K.W. |

| plasma cutting | As per plasma power source |

| software | Fast CAM |

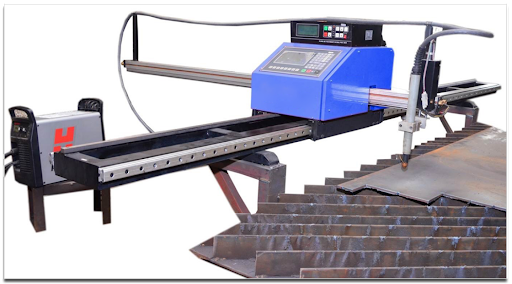

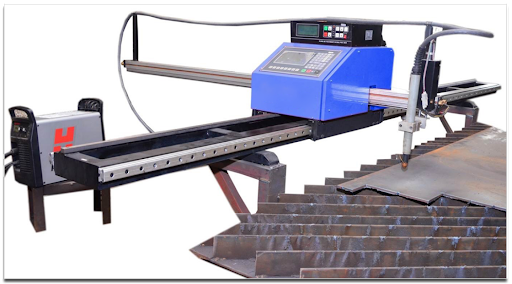

Portable Flame / Plasma Cutting Machine

We are a reputable manufacturer, supplier, and exporter of portable CNC plasma cutting machines with flames. These devices are created using the most recent technology and premium-grade parts. Additionally, India-based Pusaan Automation produces portable CNC plasma cutting machines. Our mobile flame cutting machine provides a metal with a high-quality cut. In a CNC flame cutting machine, the cutting shape is fed into the front computer and the material is often flame cut, such as tables and other items. Our machines have the capacity to carry out the task effectively and precisely. Additionally, customers can choose from a variety of models, sizes, and shapes to suit their precise needs.

You can look up other Indian companies and their prices for this machine, but we are the top producer of CNC flame/CNC plasma cutting machines in India. because we consistently give our consumers things of high quality. We make our customers a variety of offers. The machine that best meets your needs is yours to choose.

Key features of these machines are listed below:

- Sturdy construction

- Corrosion-resistant

- Scratch-resistant

- CNC system design is simple. It adopts humanistic positive man-machine conversation and it is easy to operate.

- Support flame and plasma cutting.

- Good working stability, effective shield for high frequency plasma interference, lightweight and portable.

- Standard Software: Fast CAM, used worldwide.

Many advanced features are available in these machines, which makes the machines perform well.

Portable Flame / Plasma Cutting Machine

Technical Chart

| MODAL | SC 1530 | SC 3506 |

|---|---|---|

| Track Width (mm) | 1500 | 3500 |

| Track Length (mm) | 3000 | 6300 |

| Cutting Head | One Flame and One Plasma | |

Technical Parameter

| MODAL | BEN-1530 |

|---|---|

| Cutting Mathod | Plasma & Gas |

| Width | 1500 mm |

| Length | 3000 mm |

| Cutting totch lifting | 100 mm |

| Cutting speed | 0-10,000 mm/min |

| Minimum Moving speed | 12000mm min |

| Cutting thickness | According to the plasma power source |

| Gas cutting | Oxygen + Ethyne / Oxygen + Propane |

| power | Related power 2.0 K.W. |

| plasma cutting | As per plasma power source |

| software | Fast CAM |

MODEL SCUT1530

Bench Type Plasma cutting

Model scut 1560

Portable CNC Plasma cutting

How CNC Plasma Cutting Machine work and its advantages ?

The CNC system is used by many modern technological devices and machinery types. One type of machine that makes use of computer numerical control is a CNC plasma cutter. CNC plasma cutting involves cutting through electrically conductive materials with an increased stream of hot plasma that is directed into the appropriate cutting material. This CNC plasma cutting method is widely used to cut a variety of materials, such as copper, brass, steel, and aluminium. Still, other conductive metal types can also be cut using CNC plasma cutters.

Where CNC Plasma cutting is used

There are many different environments in which CNC plasma cutters are employed. These include shops for fabrication and welding, repair facilities for cars and other vehicles, industrial construction sites, and locations where salvage operations take place. Plasma cutting has a wide range of applications and can be utilized in both large production facilities and at home by amateurs. This machine produces high-quality work. They are also inexpensive, which is another reason why you may find them in many kinds of environments.

We can characterise a typical CNC plasma cutting machine as a computer-driven system connected with a plasma torch. Thanks to mathematical coding that has been entered into a computer using CNC, the torch can be moved by the CNC machine in multiple ways. When portable plasma cutters and plasma is machines do exist, they usually do not have many of the same functions as a large CNC plasma machine. These tools are referred to as mechanized cutting machines. Automated plasma cutters use a straight barrel burner. This torch often has an interface that is CNC-controlled.

Example of a CNC Plasma Cutter

For example, cut a piece of steel. The machine uses computer numerical control exclusively to move its torch in order to cut certain sections out of this steel plate. A program consisting of M and G codes specifies the exact timing of the torch as well as the exact size of the section, ensuring that the torch is turned on and off at the appropriate moments to achieve the correct cut. The Part programmes are created by software called post-processors, which translates CAD files. Given this, your best option would be to use a CNC plasma cutter to assist in the manufacturing of anything you generate.

Advantages of Plasma Cutting Machine

- Easily cutting of all electrically conductive materials with finishing.

- Cutting easily of high-alloy aluminium and steel materials in large and medium thicknesses and gives a superior quality

- High strength structural steel cutting with low heat input

- High cutting speed (10 times more than oxyfuel)

- Any processing of high quality blank for medium and thick sheet metals

- plasma cutting give guarantees automation

- Best quality of plasma cutting under water allows very low heat exposure and low noise level at the workplace

- Plasma cutting reduces very low heat and noise levels at the underwater workplace

- The operation of one or more burners depending on the series

CNC Plasma cutting Features

- Medium heat input.

- Metallurgical perfect surfaces for welding.

- Smooth, edge surface.

- Low to high cut quality.

- High speed cutting.

- Hardening within the area of the HAZ.

- Wide range of material such as mild steel, stainless steel, and aluminium.

You can see our plasma cutting machine videos on YouTube.

We provide a complete industrial solution and also sell different types of industrial machines like fiber laser cutting machine, shearing and press brake machine, plasma cutters, welding machine, plasma and laser consumables.