Benefit Of Fiber Laser Cutting Machine

We all know that fiber laser is now well accepted in the market, and also because of the excellent advantages of good beam quality and high conversion efficiency in the company, it is widely preferred in some finishing fields. A form of active choice for products in many industrial applications, fiber lasers currently make up close to 50% of the industrial field. As frequency conversion light sources, fiber lasers have many benefits over conventional gas and solid state lasers. its characteristics, benefits, and uses. We will also discuss its features, advantages, and benefits.

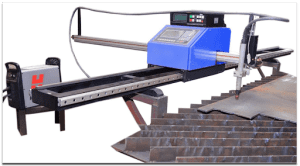

What Is A Fiber Laser Cutting Machine?

A brand-new machine in the globe that produces high energy density laser beams is the fiber laser cutting machine. The workpiece’s surface is targeted by the laser beam, which causes the area of ultra-fine focus to rapidly melt and evaporate as it moves through the CNC mechanical system. Automatic cutting through positional illumination. It has clear benefits over large volume gas lasers and solid-state lasers, and has increasingly taken on significance in industries such as high-precision laser processing, lidar systems, space technology, laser medicine, and others.

With clean and smooth edges, the optical fiber laser cutting machine can be utilised for both plane cutting and oblique cutting. It is appropriate for cutting metal plates with extreme precision. The original five axis laser can be swapped out for the manipulator at the same time for 3D cutting. It has a higher photoelectric conversion rate and uses less space and gas than a typical CO2 laser cutting machine. It is a cutting-edge technological product that also conserves energy and protects the environment.

Features Of CNC Fiber Laser Cutting Machine

1. The CNC fiber laser cutting machine has a high optical power conversion efficiency, with a conversion efficiency of above 30%. The lack of a water cooler requirement for the low power fiber laser significantly reduces operational power consumption, lowers operating expenses, and achieves the highest level of production efficiency.

2. The cost of operation and maintenance is the lowest when a laser cutting machine is in operation because it only requires electric power and does not require the production of additional laser gas.

3. The fiber laser cutting machine uses a redundancy and semiconductor modularization design. There is no start-up time and no optical lens in the resonator. Its features include adjustability, lack of maintenance, and excellent stability. They offer unmatched cost and maintenance time savings over conventional lasers.

4. The fiber laser cutter has the best cutting and welding capabilities, the best output beam quality, the highest power density, is favourable to the absorption of metal materials, and the lowest processing cost.

5. The entire machine’s optical transmission does not require a sophisticated light guide machine, such as a mirror. The optical system is easy to use, reliable, and requires little upkeep.

6. Because the cutting head has protective lenses, there is relatively little need for expensive consumables like focusing lenses.

7. Since light is produced via optical fiber, the mechanical system’s design is highly straightforward and simple to combine with robots or multi-dimensional workbenches.

8. Once the laser has been integrated into the shutter, the system can be divided into many machines, optical fiber division, multiple channels operating simultaneously, easy function expansion, simple update, and more.

9. The small volume, light weight, flexible position, and tiny area of the fiber laser cutting machine are benefits.

Applications Of Fiber Laser Cutting Machines

The use of the fiber laser cutting machine includes a variety of manufacturing and processing sectors, including sheet metal processing, aviation, aerospace, electronics, electrical appliances, tube accessories, automobiles, grain machinery, textile machinery, engineering machinery, precision accessories, ships, metallurgical equipment, lifts, home appliances, crafts, tool processing, decoration, advertising, metal processing, kitchenware processing, and others.

Materials For Fiber Laser Cutting:

Cutting of metal sheets and pipes in stainless steel, carbon steel, alloy steel, silicon steel, galvanised sheet, spring steel, aluminium, copper, silver, aluminium alloy, pickling sheet, gold, and other metals.